• Building a Nieuport 11 replica •

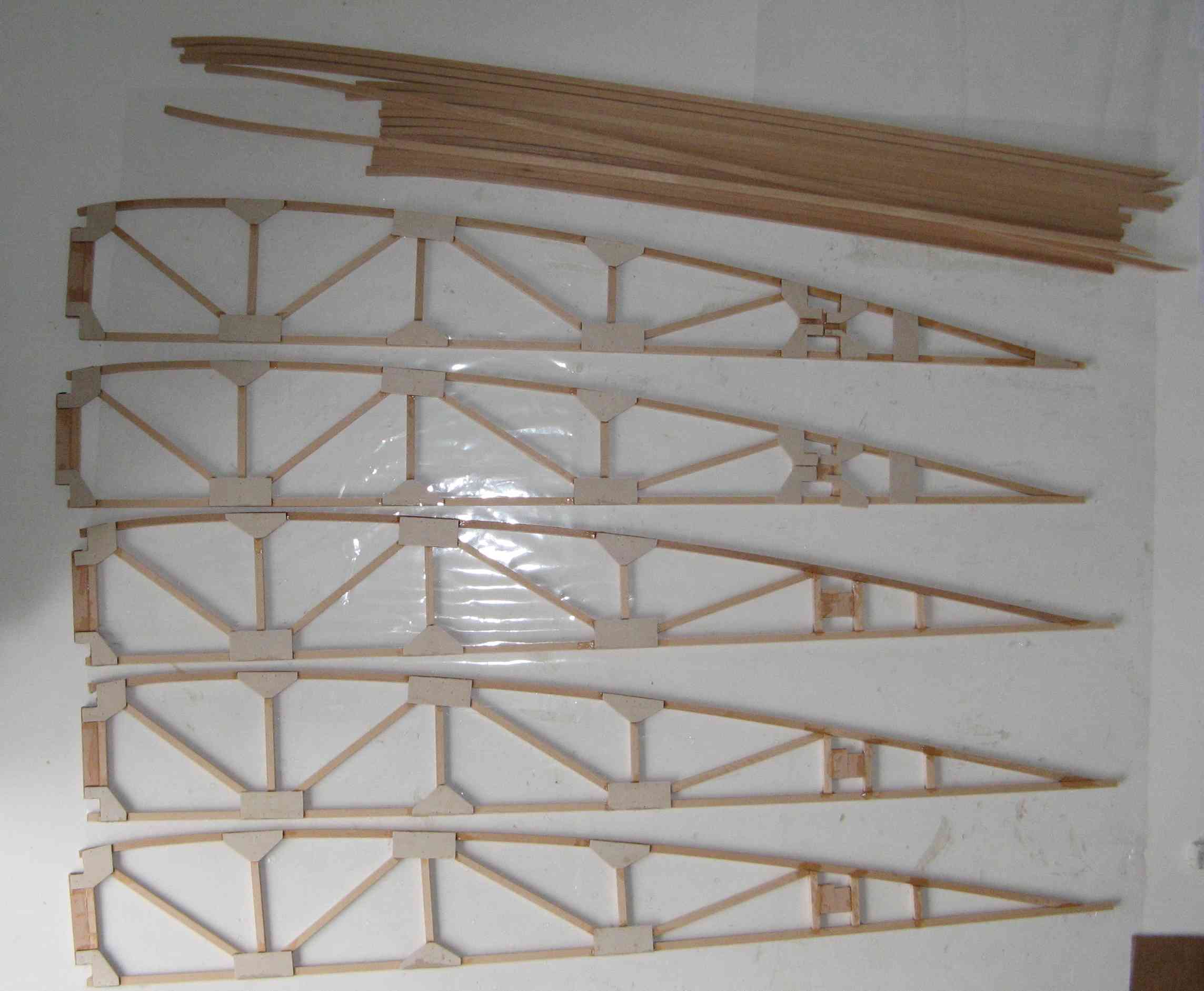

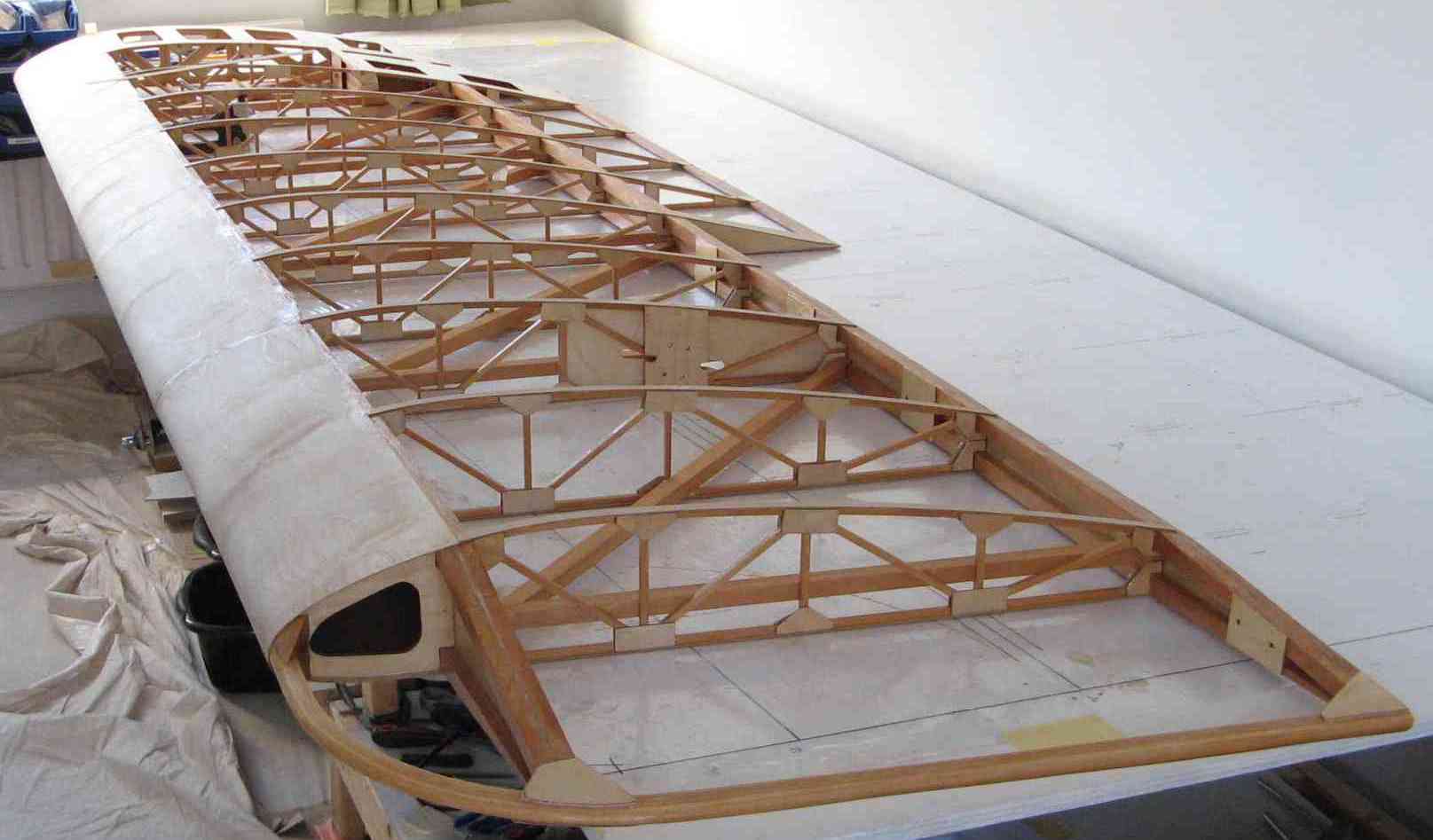

The wing ribs are made from 1/4" square spruce on the standard warren girder principle.

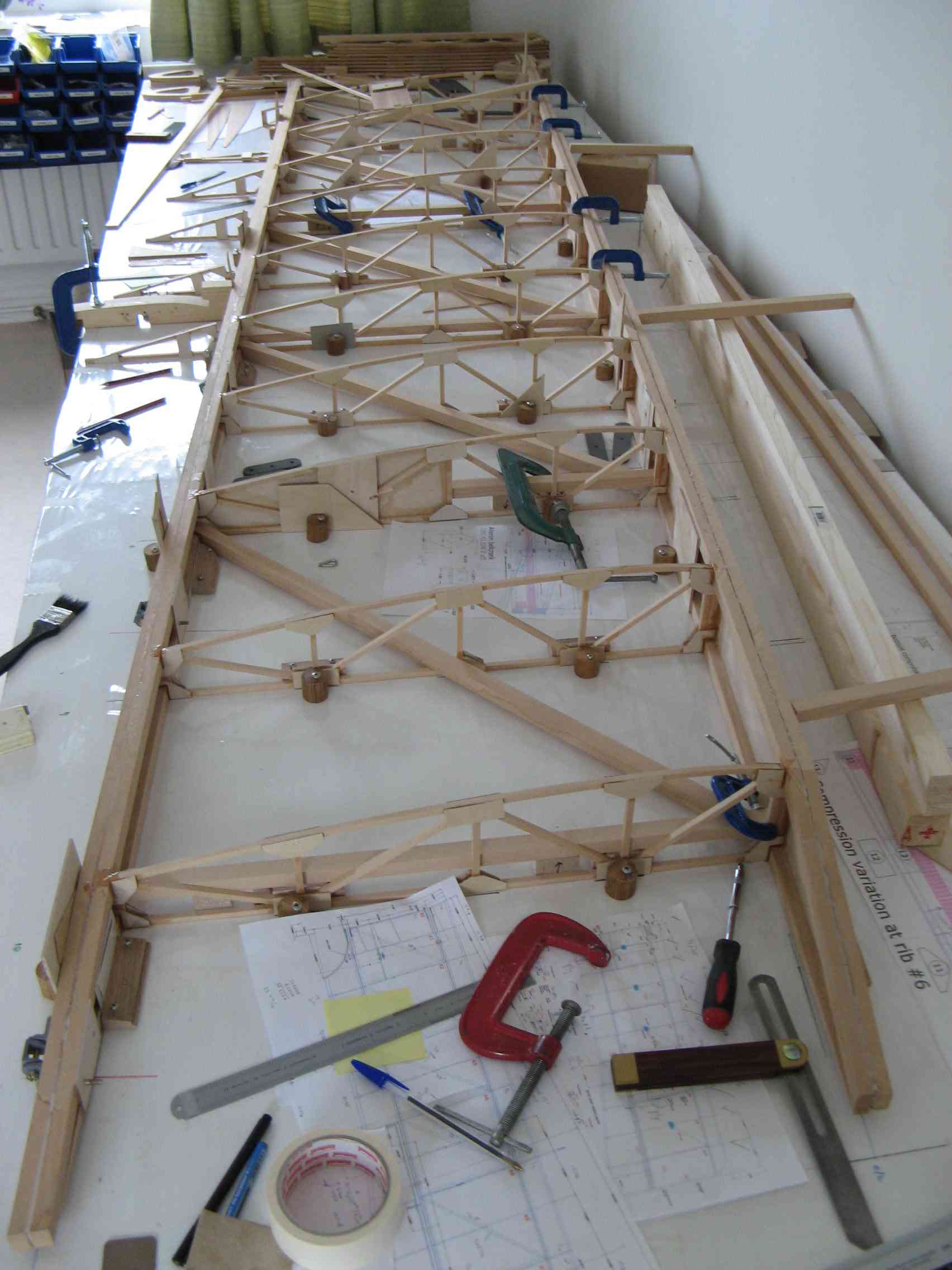

The pattern for the ribs is printed full size and a jig built by laying plastic over the pattern and attaching fixed guides and moveable cams.

The cams allow you to tighten the rib components against the fixed stops, and are made by drilling a wooden rod (in this case an old broom handle) off-centre.

The top rib strip has a fairly tight curve at the front and so the pieces were steam bent.

Several pieces were bent at a time and left to dry for a few days.

Components were cut in bulk and a production line established for the ribs.

Gussets were cut from 1/16" ply and stapled to hold the capstrips in place.

The rib could then be removed from the jig before the glue dried, and production of another rib commenced.

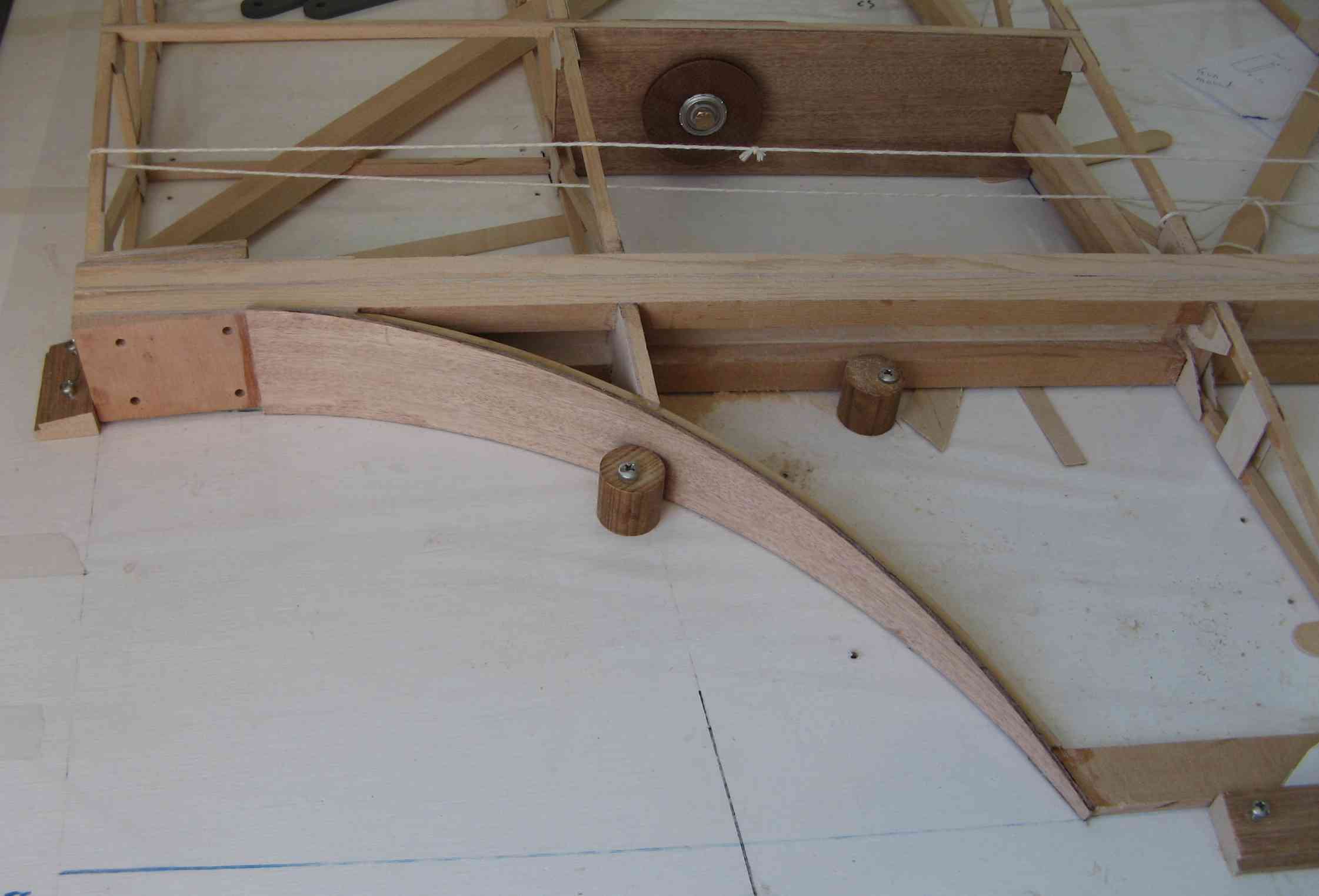

The centre section is reinforced with ply at the root, and carries the support for the aileron cable pulleys.

The centre section has a curved rear ply trailing edge to allow access to the cockpit.

This was laminated from two pieces of 1/16" okoume ply.

The wing root is covered with 1/16" ply.

The bottom section on one side has an inspection hatch so that the aileron cables can be joined.

The rectangular holes are to lighten the structure and will be fabric covered, except for the thin holes where dummy aileron levers will be attached, the hole being covered with lexan to reduce drag.

The leading edge was made up from sheets of 1.2mm ply. 3 sheets were butt joined for each wing.

The sheets were soaked in boiling water and held in place using ratchets while they dried.

Once the ply had dried the sheets were pre-varnished on the inside.

Strips were left unvarnished where they would be glued to the ribs.

Once both wings were completed they were brought together and carefully levelled so that the attachment brackets could be drilled.

A fine day was selected and the wings assembled in the garden.

The attachments and aileron cable runs were checked.

The centre section from above (wing inverted).

Some of the holes are just to lighten the structure. Others allow access to attachment bolts and the aileron cable joining plate.